The world of electronics manufacturing is filled with crucial details, from understanding cost structures to mastering component specifications. Two key areas that engineers, designers, and purchasing teams often focus on are PCB assembly price and the correct pinout of critical components like the LM358 operational amplifier. This article explores both topics to provide you with a practical overview.

What Determines PCB Assembly Price?

The PCB assembly price can vary widely depending on several factors. Whether you’re ordering a prototype or a production batch, knowing what influences the cost helps you plan your project budget effectively. Here are the main elements that impact PCB assembly pricing:

- Board Complexity

Simple single-layer PCBs are cheaper to assemble compared to multi-layer boards with dense layouts. High-density interconnect (HDI) boards, flexible circuits, or rigid-flex designs often require more precise handling, increasing costs.

- Component Types and Counts

The number and type of components significantly affect the assembly price. Using fine-pitch components like BGAs, QFNs, or ultra-small SMD parts demands advanced assembly processes, which cost more than handling basic through-hole or standard surface-mount parts.

- Assembly Technology

The choice between Surface Mount Technology (SMT), Through-Hole Technology (THT), or mixed assembly impacts pricing. SMT is generally faster and cheaper, while THT requires manual or semi-automated labor, adding to costs.

- Turnaround Time

Faster delivery times typically incur rush charges. If you need your assembled boards in a few days instead of weeks, expect a higher price for expedited service.

- Testing and Inspection Requirements

Functional testing, flying probe tests, in-circuit testing (ICT), and X-ray inspection for critical joints add to the overall assembly price. However, these services are essential for ensuring product quality and reliability.

Understanding these factors will help you balance your project’s performance requirements and cost expectations when requesting PCB assembly quotes.

LM358 Pinout Basics

When working with operational amplifiers, the LM358 is a popular and versatile choice due to its low power consumption, single-supply operation, and dual op-amp configuration. Correctly understanding the LM358 pinout is critical for integrating it into your circuit designs.

LM358 Pinout Overview

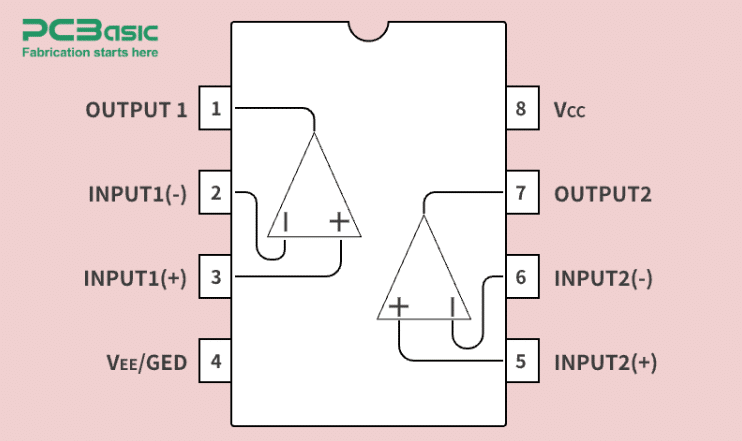

The LM358 typically comes in an 8-pin package (DIP-8 or SOIC-8). It houses two independent, high-gain operational amplifiers, each with its own input and output terminals.

Here’s a basic breakdown of the LM358 pinout:

点击图片可查看完整电子表格

- Pin 1 and Pin 7 are the output pins for each amplifier.

- Pins 2 and 3 are the inverting and non-inverting inputs for amplifier A, while Pins 5 and 6 are for amplifier B.

- Pin 4 is the ground or negative power supply.

- Pin 8 connects to the positive power supply voltage, typically between 3V and 32V for single-supply operation.

Tips for Working with LM358

- Single-Supply Friendly: Unlike traditional op-amps that require dual supplies, LM358 can operate on a single voltage source, making it ideal for battery-powered or low-voltage systems.

- Output Swing: The output can swing from ground (0V) to slightly below the positive supply (Vcc – 1.5V), which suits many general-purpose applications.

- Input Range: The input voltage range includes ground, providing more flexibility for low-voltage signal amplification.

Understanding the LM358 pinout ensures you wire it correctly and maximize the performance of your analog circuit designs.

Conclusion

Whether you’re managing your project’s costs or designing your next analog circuit, mastering the basics is essential. By understanding the key factors affecting PCB assembly price and learning the correct LM358 pinout, you can make more informed decisions, improve design reliability, and optimize production efficiency. As electronics projects become increasingly complex, these foundational skills continue to be crucial for success.