Why That Crinkly Wrapper Might Be the Smartest Business Move in Food Packaging

Next time you tear open a bag of chips, rip into a granola bar, or peel back a candy wrapper, take a closer look—not at the snack, but at the packaging.

Odds are, what you’re holding is made from roll film packaging—the unsung hero behind much of the snack aisle’s success.

So, why is roll film everywhere?

Why do snack brands—both indie and global—gravitate toward it like bees to honey (or, more accurately, like kids to gummies)?

Let’s pull back the foil and see what’s really going on.

First: What Is Roll Film Packaging?

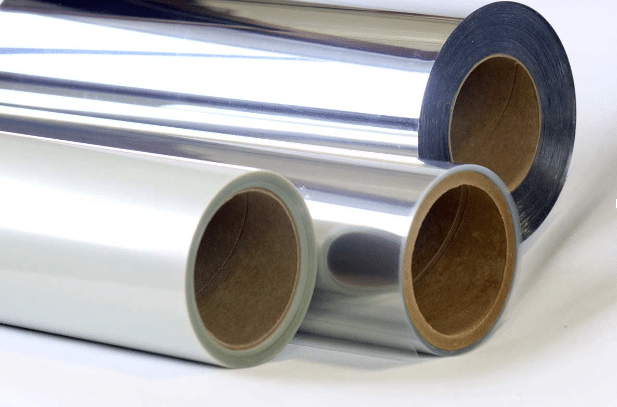

Roll film packaging (sometimes called flow wrap or form-fill-seal packaging) is a continuous sheet of printed material that’s wound onto rolls.

This is not the same as fully-constructed (whole) bags like flat bottom bags.

These rolls are loaded onto machines that:

- Form the package

- Fill it with product

- Seal it in a single, streamlined motion

It’s fast. It’s flexible. And most importantly—it’s designed for scale.

Why Snack Brands Can’t Get Enough of It

From the outside, it might just look like a convenient wrapper.

But under the surface, roll film is a strategic powerhouse for snack brands. Here’s why:

1. Speed and Scalability

- High-speed machines can package hundreds of units per minute

- Great for brands anticipating volume spikes or national retail orders

- Reduces the need for secondary packaging like boxes or sleeves

In short, it’s how small snack startups scale fast without bottlenecks in production. Think fresh drops of multiple cookie flavors in individual custom cookie bags at different days of the week!

2. Cost Efficiency That Compounds

Roll film isn’t just about affordability—it’s about optimized cost per unit.

- Uses less material than rigid or pre-formed packaging

- Ships flat (on a roll), saving on storage and transport

- Minimal waste = more efficient runs = lower production cost

The more you produce, the more roll film’s economics work in your favor.

3. Custom Branding at Full Bleed

Just because it’s efficient doesn’t mean it’s boring.

- Brands can print vibrant, full-color designs edge-to-edge

- Options include matte, gloss, metallic, kraft, and soft-touch finishes

- Transparent windows, reseal features, and embossing are all possible

With the right design, roll film can go from generic to jaw-dropping.

But Wait—Isn’t It Bad for the Planet?

It depends.

The Problem:

Traditional multi-layer roll films are notoriously difficult to recycle, often combining plastic, foil, and adhesives.

The Solution:

Innovations in mono-material roll films and recyclable PE or PP films are gaining traction fast:

- Brands can now choose roll film with certified recyclable content

- Compostable options exist, though shelf life may be shorter

- Some startups use “minimalist design” roll films with reduced ink and energy use

Bottom line: If sustainability matters to your brand (and it should), roll film is no longer the villain it once was.

Snack Brands Who Nailed It With Roll Film

Let’s look at a few brands that turned roll film into a brand-building asset for their custom snack packaging:

Hu Chocolate

Their sleek, minimal, matte-finish wrappers reinforce the brand’s health-forward mission—while being completely Instagrammable.

RxBar

Their iconic clear-font-on-color-block design has made the wrapper as recognizable as the product itself.

Partake Foods

Their allergy-friendly cookies come in bright, playful roll film that stands out on shelves and resonates with families.

How to Win With Roll Film (Even on a Budget)

1. Invest in Killer Design

You only get one panel—make it unforgettable. Roll film is unforgiving when poorly designed, but striking when done right.

Tips:

- Use contrast to create visual hierarchy

- Stick to one or two fonts

- Don’t overload with text—clarity wins

2. Choose the Right Film Type

Depending on your product, you’ll want to match barrier properties and shelf-life needs.

Common roll film types:

- OPP: Great for dry snacks, candy bars, chips

- PET/PE: Used for products that need better protection or heat resistance

- Kraft laminates: For an artisanal or organic look

3. Test With Short Runs First

Many digital roll film converters now offer low minimum order quantities (MOQs)—perfect for:

- Product launches

- Seasonal flavors

- Limited edition drops

Even indie brands can test new SKUs without committing to thousands of units.

The Unspoken Benefit: Perceived Value

Despite its low cost, roll film doesn’t look cheap when executed well.

In fact, the crisp seals, tactile finishes, and print potential make it a sleek, modern way to convey professionalism. Especially in the snack world, where “eye appeal” often leads to impulse buys, roll film helps products feel premium—even when priced accessibly.

Final Thoughts: The Wrapper Is Part of the Product

Roll film isn’t just a practical tool. It’s part of the customer experience.

From the sound it makes when torn open, to the gloss or matte feel between fingers, to how quickly it communicates brand cues—every detail adds up. And in the snack industry, where brand loyalty is fragile and choices are infinite, these details matter.

So the next time you see a sleek snack wrapper on a shelf, remember: It’s not just about what’s inside. The wrapper is doing its job, too.

And now you know the secret behind its obsession.