Floor jacks are essential tools in automotive maintenance and repair. They provide the muscle needed to lift vehicles safely, enabling mechanics and DIYers to perform vital tasks beneath the chassis. Despite their rugged appearance and dependable function, floor jacks rely on precision-engineered hydraulic systems that require regular maintenance to ensure peak performance and safety. This article focuses on the technical aspects of maintaining a floor jack, offering a comprehensive hydraulic health check that can extend the tool’s lifespan and prevent critical failures.

Understanding the Hydraulic System

At the heart of every floor jack is a hydraulic system that utilizes fluid pressure to amplify force. This typically includes a reservoir, pump piston, release valve, and lifting arm. When the jack handle is pumped, hydraulic fluid is pushed into a cylinder, causing the lifting arm to rise. The entire process depends on the integrity and cleanliness of the hydraulic fluid and the precision of moving components.

Hydraulic systems are susceptible to wear and degradation over time. Air can become trapped in the fluid, seals can wear out, and contaminants can enter the reservoir. Without routine checks and maintenance, these issues can cause the jack to operate sluggishly—or worse, fail during use, creating a significant safety risk.

The Hydraulic Health Check: Step-by-Step

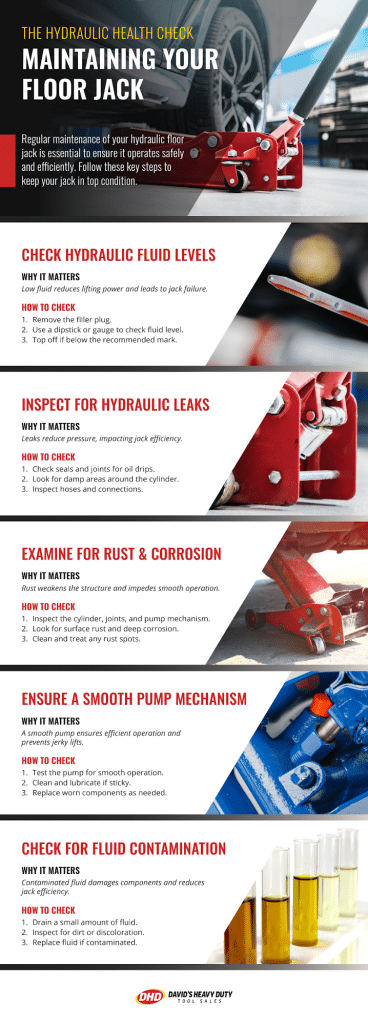

- Inspect for Visible Leaks

Start by checking around the base, piston, and handle connection points for hydraulic fluid leaks. A small leak can indicate a deteriorating O-ring or seal. If left unchecked, leaks reduce hydraulic pressure, making the jack unreliable. - Check the Fluid Level

Always refer to the manufacturer’s manual for the correct hydraulic fluid type. Remove the fill plug and ensure the fluid level is near the top of the reservoir. Low fluid can cause incomplete lifts or a spongy feel when pumping. - Bleed the System

Air bubbles in the hydraulic system reduce lifting power. To bleed the jack, fully open the release valve, pump the handle several times, then close the valve and test the lift. Repeat until the jack operates smoothly. - Clean and Lubricate Moving Parts

While the hydraulic system does the heavy lifting, the jack’s performance also depends on the smooth operation of hinges, wheels, and the lifting arm. Use a light lubricant on pivot points and clean off any debris or buildup. - Test the Lifting Capacity

Place a known weight near the jack’s rated capacity and perform a test lift. If the jack struggles or descends under load, it may be time to replace the seals or perform a full rebuild.

Advanced Maintenance Tips

Technologically advanced users may consider retrofitting older jacks with pressure sensors or fluid-level indicators. These upgrades provide real-time data about the hydraulic system’s status and can alert users to problems before they become failures. Additionally, using a digital torque wrench to secure fasteners on the jack ensures that components remain tightly assembled without the risk of over-tightening, which can warp parts or damage threads.

Regular calibration of your jack, especially in professional settings, is another overlooked but crucial step. Similar to a 4400 lb transmission jack that must meet specific safety and performance standards, your floor jack must be regularly verified for accuracy and reliability.

Safety Comes First

A faulty jack is more than an inconvenience—it’s a potential hazard. Never work beneath a vehicle supported only by a jack. Always use jack stands and double-check for stability before proceeding with repairs. Routine maintenance, combined with careful use, ensures that your floor jack remains a dependable tool in your garage arsenal.

Maintaining your floor jack is as much about technology as it is about safety. A well-maintained hydraulic system delivers reliable lifting performance and extends the life of your equipment. By conducting regular hydraulic health checks—looking for leaks, checking fluid levels, bleeding air, and ensuring mechanical integrity—you invest in both your tools and your safety. Whether you’re lifting a compact car or positioning a jack beneath a heavy-duty truck, attention to detail and regular maintenance will keep your hydraulic tools in top shape.